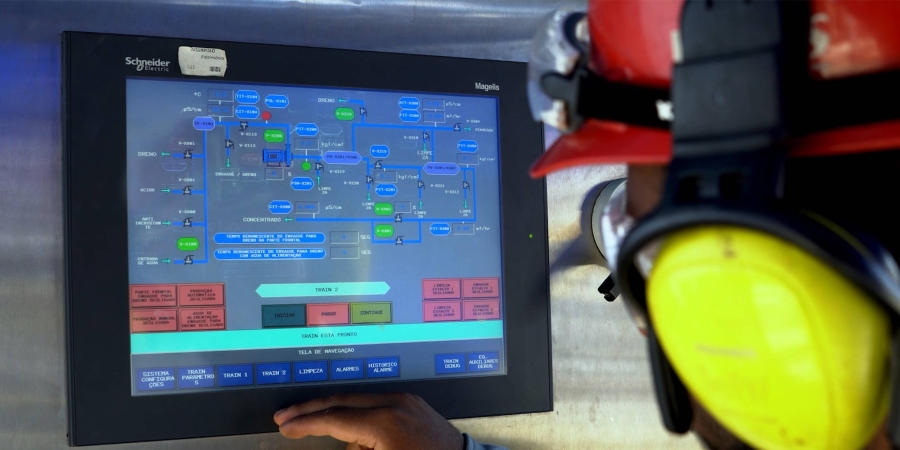

Aquapolo, Brazil's largest wastewater treatment plant, partnered with Schneider Electric to address the growing demand for water for industrial use while reducing operating costs and increasing efficiency. The EcoStruxure for Water and Wastewater solution, including leading-edge industrial software from AVEVA, also helped it to improve its regulatory compliance, increasing its industrial sustainability.

Aquapolo needed to:

- Address a severe shortage of potable water for the local community

- Meet the increasing demand for water for industrial use

- Manage 20 different KPIs related to water quality and quantity

- Reduce production costs

- Improve operational efficiency